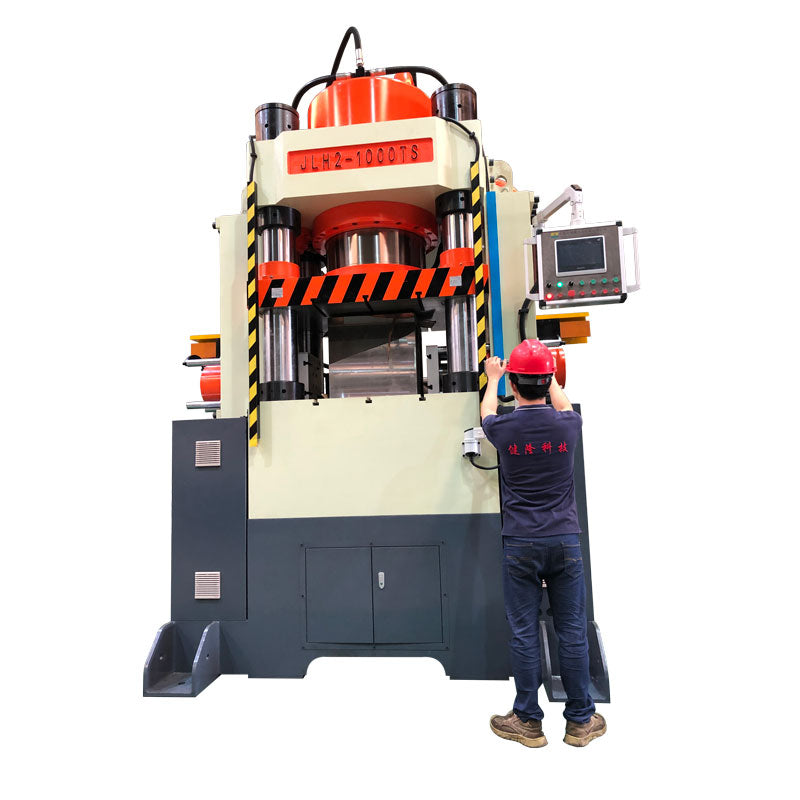

Four-column cold extrusion forming machine

Four-column cold extrusion forming machine

无法加载取货服务可用情况

A cold extrusion forming hydraulic press is a device that uses hydraulic energy to drive the mold to perform extrusion forming on metal billets at room temperature. Due to its ability to achieve high pressure and high precision forming, it has a wide range of applications and covers multiple industrial fields. The following is an introduction to its main application areas:

1. Automotive manufacturing

The automotive industry is one of the main application fields of cold extrusion forming hydraulic presses. A large number of components are produced through cold extrusion technology to meet the requirements of high strength and high precision:

Engine components: such as valve tappets, piston pins, connecting rods, gear blanks, etc., cold extrusion can ensure the continuous distribution of metal fibers in these parts, improving their mechanical properties.

Chassis components: including half shafts, differential gears, steering knuckles, transmission shaft splines, etc., cold extrusion forming can reduce the subsequent processing volume and improve production efficiency.

Transmission components: such as synchronizer ring, gear shafts, etc., through cold extrusion, high dimensional accuracy and surface quality can be obtained, ensuring the stable operation of the transmission.

2. Mechanical manufacturing

In general mechanical manufacturing, cold extrusion forming hydraulic presses are used to produce various structurally complex and performance-demanding parts:

Fasteners: high-strength bolts, nuts, rivets, etc., cold extrusion forming not only improves their strength but also enables mass production.

Bearing parts: bearing inner rings, outer rings, raceways, etc., cold extrusion can ensure the dimensional accuracy and surface roughness of the parts, prolonging the service life of the bearings.

Tool parts: such as the heads of wrenches and screwdrivers, cold extrusion can make the parts have good mechanical properties and durability.

3. Aerospace field

This field has extremely high requirements for the strength, precision and reliability of parts. Cold extrusion forming hydraulic presses play an important role:

Aircraft engine parts: such as blades, engine casings, etc., cold extrusion can improve the fatigue strength and high-temperature resistance of the parts.

Spacecraft structural parts: such as brackets, connecting pieces, etc., cold extrusion forming can reduce the weight of the parts while ensuring structural strength.

4. Electronic and electrical field

In the electronic and electrical industry, some small and precise parts are produced using the cold extrusion forming process:

Motor parts: such as rotor, stator silicon steel sheets, etc., cold extrusion can ensure the dimensional accuracy and magnetic conductivity of the parts.

Connector parts: such as contact pieces of plugs and sockets, cold extrusion forming can improve the conductivity and wear resistance of the parts.

5. Hardware products field

Many hardware products are produced using cold extrusion forming hydraulic presses, featuring high production efficiency and low cost:

Daily-use hardware: such as keys, zipper pulls, scissors heads, etc., cold extrusion can make the products have a beautiful shape and reliable performance.

Building hardware: such as hinges, bolts, nuts, etc., cold extrusion forming can meet the strength requirements of building parts.

In summary, cold extrusion forming hydraulic presses, with their unique forming advantages, have important applications in multiple industrial fields. With the continuous development of technology, their application scope will further expand.

Share