Hot forging hydraulic press is used for metal and non-metal parts in automotive parts, LED radiators, hardware tools and other cold extrusion stamping forgings and shallow stretch forming industries. The hot forging hydraulic press adopts PLC programming circuit design and touch screen operating system to realize digital control, making the machine run more stable, safer and more efficient.

| Moswl | Unit | Product specifications | ||||

| JLA3-300T | JLA3-500T | JLA3-650T | JLA3-800T | |||

| Master cyinder | Capacity | ton | 300 | 500 | 650 | 800 |

| Stroke | mm | 400 | 500 | 500 | 500 | |

| Down speed | mm/s | 160 | 180 | 165 | 165 | |

| Press speed | mm/s | 8-12 | 8-15 | 8-16 | 8-16 | |

| Return speed | mm/s | 130 | 150 | 160 | 160 | |

| Ejector cylinder | Capacity | ton | 30 | 40 | 50 | 50 |

| Stroke | mm | 200 | 200 | 250 | 250 | |

| Dia.Of ejector bar | mm | Φ50 | Φ50 | Φ80 | Φ80 | |

| Working table size | L-R(Cylinder) | mm | 700 | 800 | 1000 | 1000 |

| F-B(edge) | mm | 700 | 800 | 1000 | 1100 | |

| Open height | mm | 700 | 800 | 900 | 1000 | |

| Motor power | kw | 22 | 37 | 37 | 59 | |

| Note: the above parameters are for reference only, order according to the contract. | ||||||

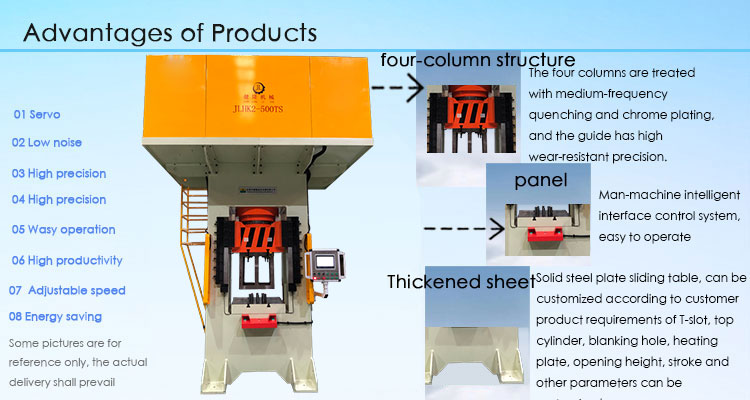

Technical features:

Jianlong brand hot forging hydraulic press adopts servo system, touch screen operation interface. In addition, the dry sound is small, energy saving and high efficiency, hot forging hydraulic press also has the following advantages:

1). The pressure, stroke, pressure holding, cold and hot forging can be adjusted according to the process requirements.

2). The column adopts high strength alloy steel plated with hard chromium, good wear resistance and long service life.

3). The operating system supports three languages: Chinese, English and the customer's native language.

4). According to the process requirements, you can set the cold extrusion printing or hot forging function, very flexible.

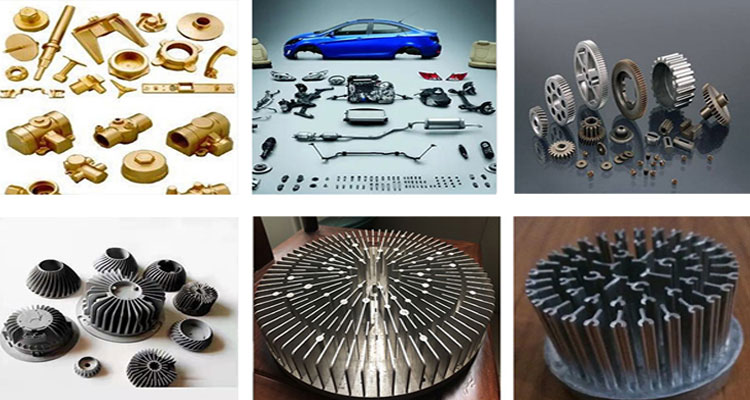

Scope of application:

1.LED lamp radiator, auto parts and other products cold extrusion molding, imprint

2. Motorcycle parts, mobile phone shell, LED radiator, watchband, watch case, hardware tools, etc

3, gold jewelry, glasses, compound mold, nameplate and automotive interior products molding

4, metal or non-metal cold extrusion forming, stamping, shallow drawing, blanking and other uses

Dongguan Jianlong Hydraulic Machinery Co., Ltd. is located in the manufacturing city Dongguan. Headquartered in Liaobu Town, Dongguan City, the company has set up international business division, Guangxi, Shanghai, Hubei offices.,The company with integrity, strength and product quality to win industry recognition, welcome friends from all walks of life to visit Jianlong hydraulic technology visit, guidance and business negotiation.

Our office

Our workshop

The company is proficient in all kinds of hydraulic machinery design, manufacturing, sales and other services, the main products are: Servo multi-direction (3D) forging press, servo four-column double action tension hydraulic press, servo jigsaw hydraulic press, servo four-column hydraulic press, servo cold forging machine, servo hot press, servo die casting edge cutting machine, servo frame hydraulic press, servo sheet metal shaping hydraulic press, servo bow (C) shape machine, hydraulic press press and other hydraulic equipment.

Packaging and Transportation

Qualification certificate

The company has passed ISO9001:2015 international quality, integrity management, after-sales service, CE and other system certification, has a complete and scientific quality system.

Our Exhibition

Contact: Li Fuyan

Phone: 18988729072

E-mail: lifuyan45@gmail.com

Whatsapp:0086-18988729072

Add: Guangyi Industrial Park, No.2 Jinfu West Road, Tanglip, Liaobu Town, Dongguan City, Guangdong Province, China

We chat