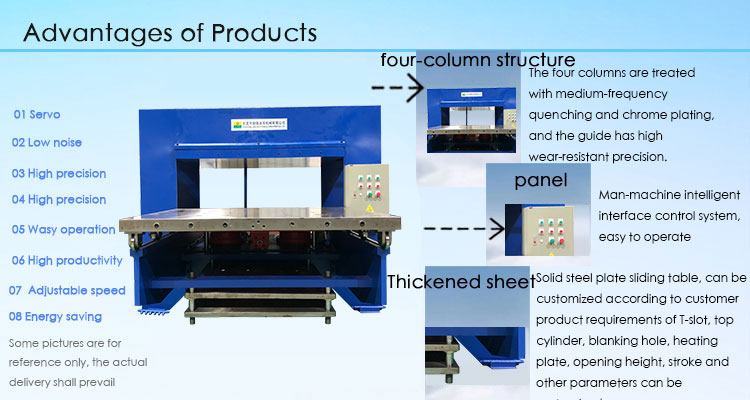

Hot pressing carbon fiber hydraulic press, also known as composite material molding machine, using composite material molding, belongs to the multi-functional hydraulic press equipment, according to the size and shape of the pressed carbon fiber products, choose the appropriate hydraulic press model, equipment replacement mold, you can process a variety of carbon fiber products, to achieve a multi-purpose machine. Carbon fiber material hot pressing machine adopts full CNC servo control, in the forming of carbon fiber products, the forming machine can be arbitrarily set pressure value, speed, position, pressure holding time, opening speed and so on.

Technical characteristics of hot-pressed carbon fiber hydraulic press:

High precision: carbon fiber products usually have high requirements for the accuracy of size and shape, and carbon fiber products molding hydraulic press can achieve high precision molding by precisely controlling the parameters of the hydraulic system. By adjusting the liquid pressure and speed, the tightness of the carbon fiber fabric and the thickness of the fiber layer can be controlled to ensure the accuracy and consistency of the product.

High efficiency: Hot pressed carbon fiber hydraulic press (composite molding press) has fast movement speed and response ability. It can apply high pressure in a short time to complete the compaction and molding tasks of carbon fiber fabrics. Compared with the traditional mechanical molding equipment, the action of the hydraulic press is faster, more stable, and the production efficiency is higher.

Uniform pressure distribution: The hydraulic press provides uniform pressure through the hydraulic cylinder to ensure that the carbon fiber fabric is subjected to uniform pressure distribution during the molding process. This uniform pressure distribution can prevent the carbon fiber fabric from breaking, wrinkling or producing bubbles and other defects, improving the quality and strength of the product.

Flexibility and adaptability: Carbon fiber molding hydraulic press is suitable for carbon fiber molding of different shapes, sizes and thicknesses. By changing the molding mold and adjusting the hydraulic parameters, it can adapt to various molding needs and provide flexible and diverse molding schemes.

Safety: The hot-pressed carbon fiber hydraulic press (composite molding press) is equipped with multiple safety protection devices, such as overload protection, emergency shutdown devices, etc., to ensure the safety of operators and equipment. In addition, the hydraulic system is well sealed, will not produce open flame and harmful gases, more safe and reliable.

Carbon fiber hot pressing hydraulic press scope:

1, fiber materials: carbon fiber, glass fiber and other decorative parts molding.

2, composite materials: PC/PMMA/ABS and other composite plate film molding.

3, insulation materials: aerogel, cold gel, silica gel, PET, filter and other insulation materials molding.

Dongguan Jianlong Hydraulic Machinery Co., Ltd. is located in the manufacturing city Dongguan. Headquartered in Liaobu Town, Dongguan City, the company has set up international business division, Guangxi, Shanghai, Hubei offices.,The company with integrity, strength and product quality to win industry recognition, welcome friends from all walks of life to visit Jianlong hydraulic technology visit, guidance and business negotiation.

Our office

Our workshop

The company is proficient in all kinds of hydraulic machinery design, manufacturing, sales and other services, the main products are: Servo multi-direction (3D) forging press, servo four-column double action tension hydraulic press, servo jigsaw hydraulic press, servo four-column hydraulic press, servo cold forging machine, servo hot press, servo die casting edge cutting machine, servo frame hydraulic press, servo sheet metal shaping hydraulic press, servo bow (C) shape machine, hydraulic press press and other hydraulic equipment.

Packaging and Transportation

Qualification certificate

The company has passed ISO9001:2015 international quality, integrity management, after-sales service, CE and other system certification, has a complete and scientific quality system.

Our Exhibition

Contact: Li Fuyan

Phone: 18988729072

E-mail: lifuyan45@gmail.com

Whatsapp:0086-18988729072

Add: Guangyi Industrial Park, No.2 Jinfu West Road, Tanglip, Liaobu Town, Dongguan City, Guangdong Province, China

We chat