1, the use of advanced hydraulic system, hydraulic system failure less, high reliability and small reversing impact.

2. The four columns are made of high strength alloy steel, with hard chrome plating on the surface and good wear resistance.

3, the core hydraulic electrical parts using Germany, the United States, Japan, Taiwan imported products, quality assurance.

4, lengthened oriented design, good guidance, high accuracy.

5. Continuous circulating cooling oil temperature system reduces the oil temperature when the machine is running.

6, the movable table is equipped with the upper die stripping oil cylinder, convenient for the upper die stripping.

7. Italian brand motor and human-machine intelligent interface control system are adopted

| Technical table of multidirectional forging press | |||||

Model project/ type | Unit | JLA1-200T | JLA1-400T | JLA1-600T | |

| Nominal capacity | kn | 2000 | 4000 | 6000 | |

Max.Working pressure | mpa | 21 | 22 | 24 | |

| Main cylinder stroke | kn | 1500 | 2500 | 4000 | |

| Gushion cylinder capacity | kn | 500 | 1500 | 2000 | |

| Ejection cqpacity | kn | 60 | 60 | 60 | |

Max.Stroke of ram | mm | 650 | 900 | 1200 | |

Max.stroke of cushion piston | mm | 250 | 250 | 350 | |

| Max.Steoke of ejection | mm | 180 | 280 | 280 | |

| Max.Open height | mm | 850 | 1200 | 1500 | |

| Speed of ram | Down no load | mm/s | 300 | 300 | 270 |

| Pressing | mm/s | 15/30 | 13/18 | 13/21 | |

| Return | mm/s | 250 | 230 | 230 | |

| Effective bench area | Left and right (edge) | mm | 1000 | 1400 | 2000 |

| Front and back (edge) | mm | 850 | 1200 | 1500 | |

| Motor power | kw | 18.5 | 37 | 55 | |

| Note: the above parameters are for reference only, order according to the contract. | |||||

Technical features:

1, the use of advanced hydraulic system, hydraulic system failure less, high reliability and small reversing impact.

2. The four columns are made of high strength alloy steel, with hard chrome plating on the surface and good wear resistance.

3, the core hydraulic electrical parts using Germany, the United States, Japan, Taiwan imported products, quality assurance.

4, lengthened oriented design, good guidance, high accuracy.

5. Continuous circulating cooling oil temperature system reduces the oil temperature when the machine is running.

6, the movable table is equipped with the upper die stripping oil cylinder, convenient for the upper die stripping.

7. Italian brand motor and human-machine intelligent interface control system are adopted

Scope of application:

1, tableware, kitchen sink and pot liner, electric motor metal shell, auto sheet metal tensile parts, cover plate and lighting cover shell parts and other products of tensile molding.

2, metal or non-metal parts of stretching, also suitable for product pressing, punching and other processing operations.

Dongguan Jianlong Hydraulic Machinery Co., Ltd. is located in the manufacturing city Dongguan. Headquartered in Liaobu Town, Dongguan City, the company has set up international business division, Guangxi, Shanghai, Hubei offices.,The company with integrity, strength and product quality to win industry recognition, welcome friends from all walks of life to visit Jianlong hydraulic technology visit, guidance and business negotiation.

Our office

Our workshop

The company is proficient in all kinds of hydraulic machinery design, manufacturing, sales and other services, the main products are: Servo multi-direction (3D) forging press, servo four-column double action tension hydraulic press, servo jigsaw hydraulic press, servo four-column hydraulic press, servo cold forging machine, servo hot press, servo die casting edge cutting machine, servo frame hydraulic press, servo sheet metal shaping hydraulic press, servo bow (C) shape machine, hydraulic press press and other hydraulic equipment.

Packaging and Transportation

Qualification certificate

The company has passed ISO9001:2015 international quality, integrity management, after-sales service, CE and other system certification, has a complete and scientific quality system.

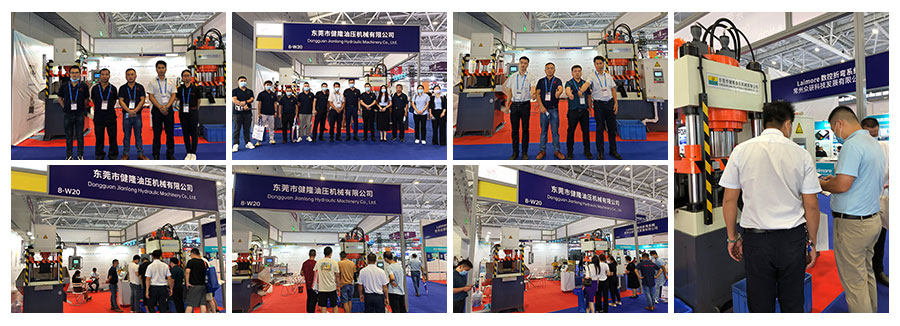

Our Exhibition

Contact: Li Fuyan

Phone: 18988729072

E-mail: lifuyan45@gmail.com

Whatsapp:0086-18988729072

Add: Guangyi Industrial Park, No.2 Jinfu West Road, Tanglip, Liaobu Town, Dongguan City, Guangdong Province, China

We chat